3D Design

And Modelling

Welcome to the world of 3D printing, where imagination meets innovation, and the extraordinary becomes reality. Our technology empowers creators to bring their boldest visions to life with precision and intricacy previously unattainable through traditional manufacturing methods. .

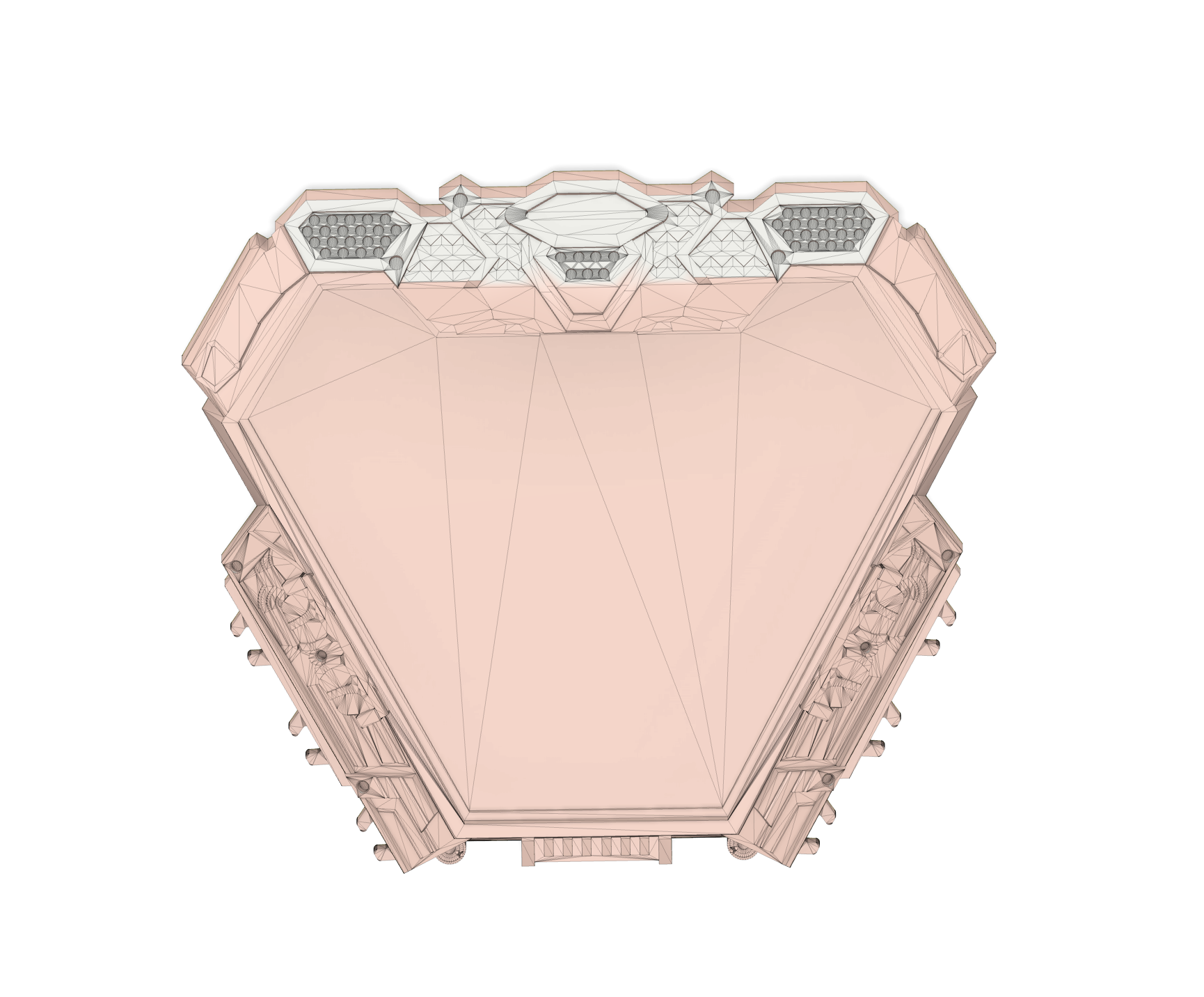

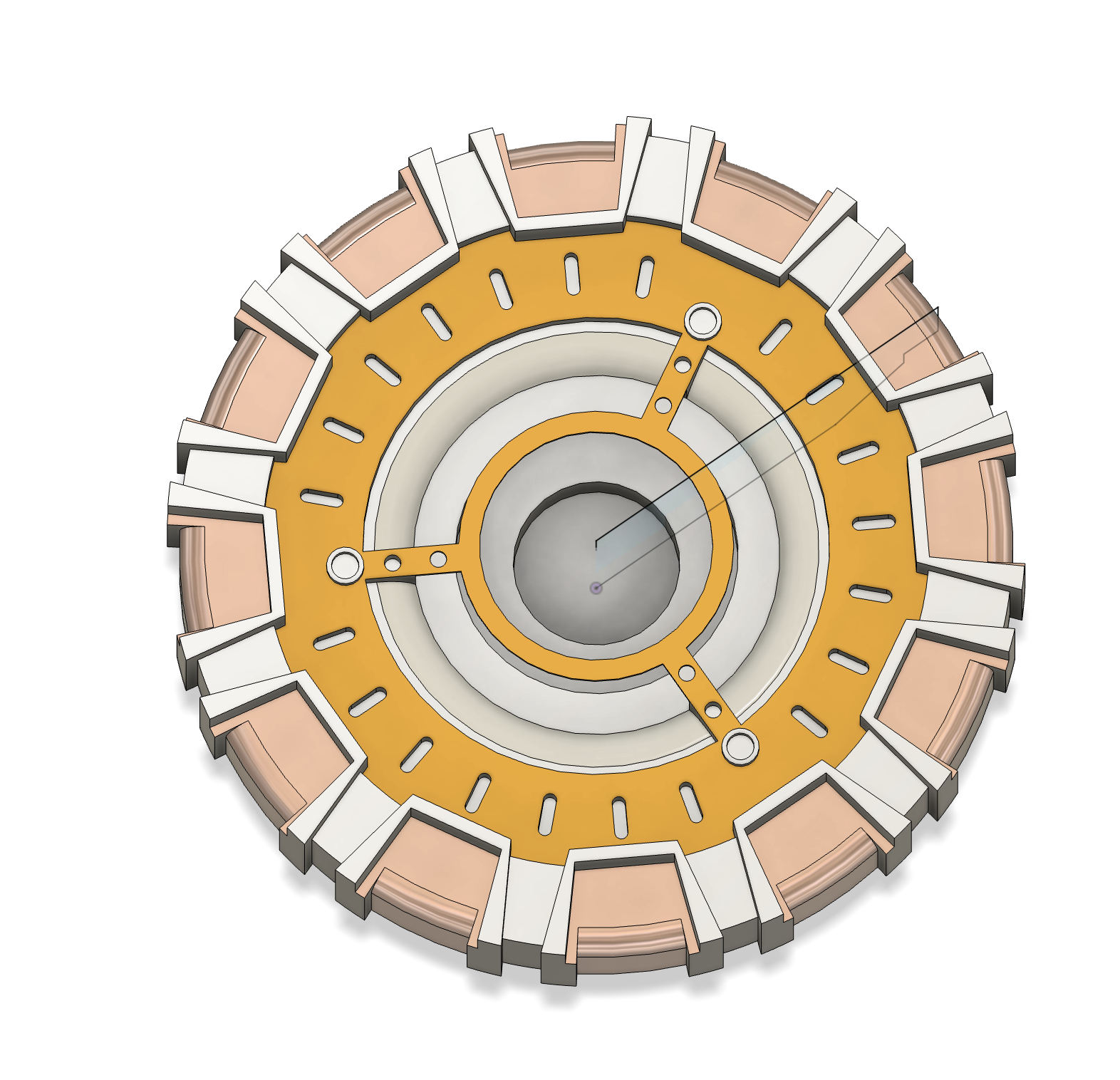

At our forefront stands the iconic Iron Man Arc Reactor, a symbol of ingenuity and heroism from the Marvel Cinematic Universe. Beyond being ardent fans of Iron Man, we are drawn to the challenge this complex design presents. The Arc Reactor, with its intricate details and futuristic allure, represents the pinnacle of 3D printing craftsmanship.

Utilizing cutting-edge software like Fusion 360, we embark on a journey to replicate Stark's masterpiece. This powerful CAD tool equips us with the capability to tackle the most intricate designs, pushing the boundaries of what's possible with additive manufacturing.

Layer by layer, the Arc Reactor takes shape, each pass of the printer head bringing us closer to our goal. With meticulous attention to detail and unwavering dedication, we watch as our vision materializes into a tangible reality. This process exemplifies the fusion of creativity and technology, showcasing the transformative potential of 3D printing.

Beyond mere replication, our endeavor embodies the spirit of innovation and imagination that defines our craft. The Iron Man Arc Reactor serves not only as a tribute to a beloved character but also as a testament to the limitless possibilities of additive manufacturing. Join us on this journey as we continue to push the boundaries of what's possible and inspire the next generation of creators.

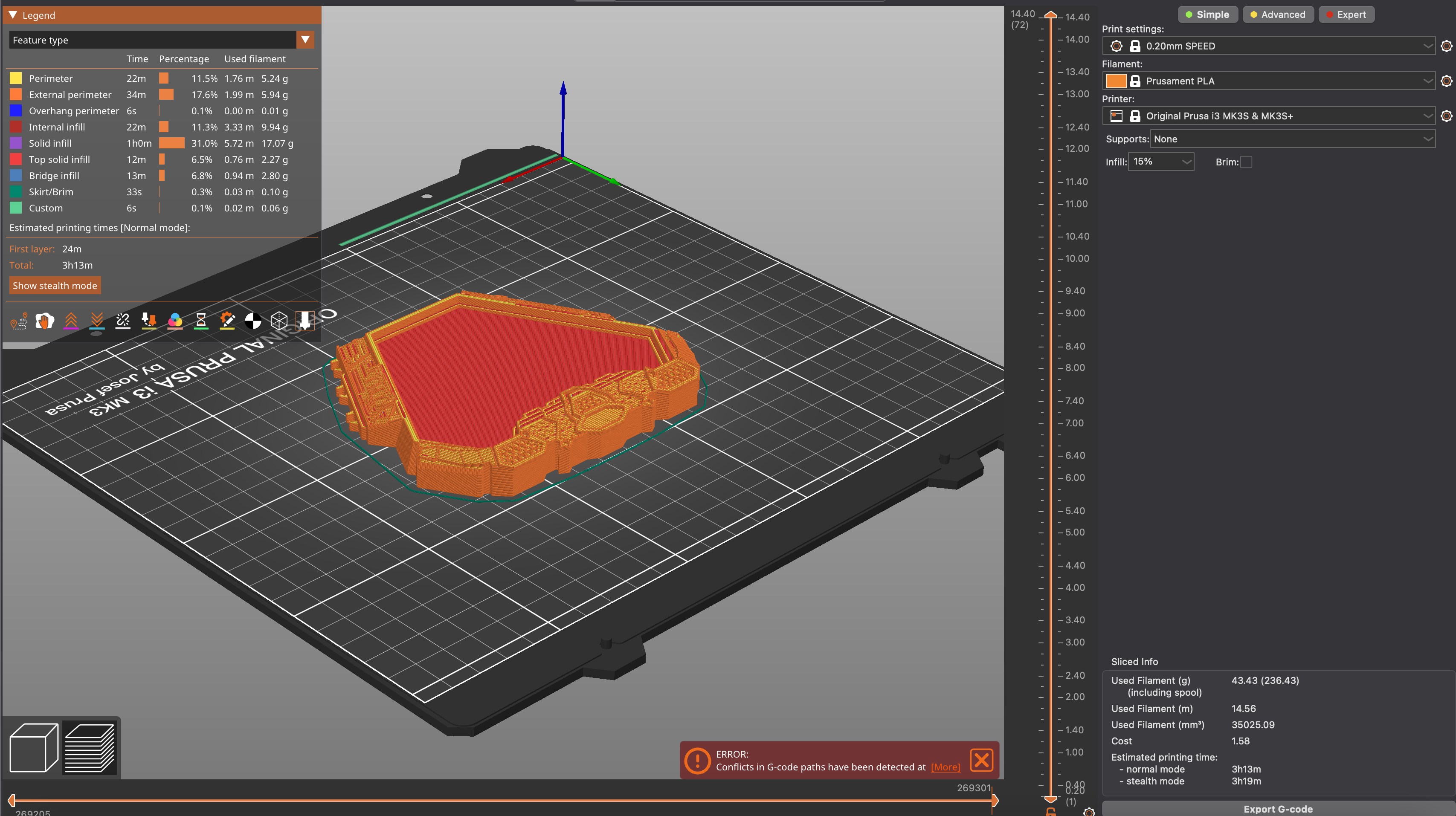

Final Output

For the printing process, I opted to use PrusaSlicer, a powerful slicing software known for its user-friendly interface and advanced features. PrusaSlicer enabled me to prepare my 3D models for printing with ease, allowing me to adjust settings such as layer height, infill density, and print speed to achieve optimal results.

Learnings From fusion 360

Learning the ropes of 3D modeling software like Fusion 360 was no small feat. It took countless hours of experimentation, exploration, and a multitude of tutorials to grasp the intricacies of the tools at my disposal. From mastering the art of sketching to understanding the nuances of parametric modeling, each step forward felt like a triumph in itself.

Among the arsenal of tools offered by Fusion 360, several proved to be indispensable in bringing the Arc Reactor to life. The versatility of the sketching tools allowed me to meticulously outline every curve and contour, while the sweep and loft features enabled me to create the intricate patterns that adorn the reactor's surface. Additionally, the array of fillet and chamfer options provided the finesse needed to refine the finer details of the design.

Navigating through the intricacies of Fusion 360, I found solace in the wealth of tutorials available online. From step-by-step guides to comprehensive video tutorials, each resource served as a beacon of guidance, illuminating the path forward in my quest to master the art of 3D modeling. In particular, YouTube proved to be an invaluable resource, offering a plethora of instructional videos that catered to every skill level and learning style.

With each tutorial watched and every technique learned, I grew more confident in my abilities to tackle the challenge at hand. Armed with newfound knowledge and a steadfast determination, I embarked on the journey to bring the Iron Man Arc Reactor to life through the magic of 3D printing. And though the road was fraught with challenges and setbacks, the satisfaction of seeing my vision materialize into a tangible reality made every moment of the journey worthwhile.

Along the way, I encountered a few bumps in the road. Despite my best efforts, there were some versions of the Arc Reactor model that didn't quite meet my expectations. They lacked the level of detail and accuracy I was aiming for, and no matter how much I tweaked them, they just didn't seem to capture the essence of the original design.

Tried versions

Moving Towards The Final Project

For my final project involving drones, I scoured the internet in search of existing drone models that could potentially serve as the foundation for my project. However, as I delved deeper into the intricacies of drone design, I realized that certain components, such as the propellers and drone parts, posed unique challenges.

Specifically, 3D printing the propellers and other drone components requires a deep understanding of aerodynamics and precise design. Unfortunately, at the current stage of my knowledge and expertise, I lack the necessary proficiency in these areas.

Although it may seem daunting now, I'm confident that with dedication and effort, I'll eventually gain the expertise needed to create drone components with the precision required for my project